With new overtime laws in California and Washington and sky rocketing fuel prices, growers need to optimize their 9-hour spraying shifts to cover as many acres as possible without sacrificing the spray quality. With this notion in mind, there are a few areas of spraying shifts that can be optimized. Refilling is a major one as Fieldin found after evaluating data across more than 300,000 spraying shifts.

When crews are waiting their turn at refill stations or nurse trucks, driving longer distances than necessary, using refills as an excuse for extra break time, or refilling with low pressure, all of this time adds up – time that could be spent covering significantly more acres per shift (up to 25% in many cases).

At Fieldin, we’ve found that refill inefficiencies occur in nearly 95% of spraying shifts.

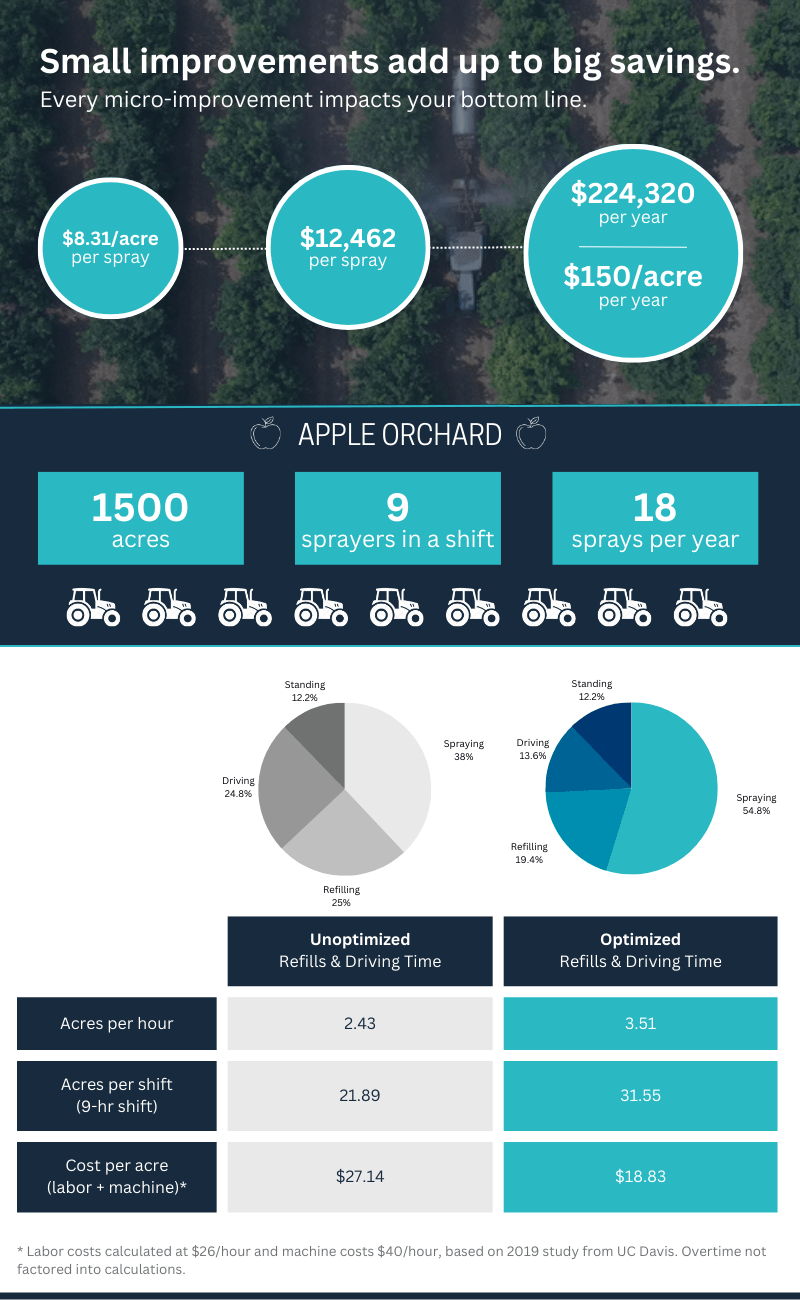

Saving $150/acre by changing behavior

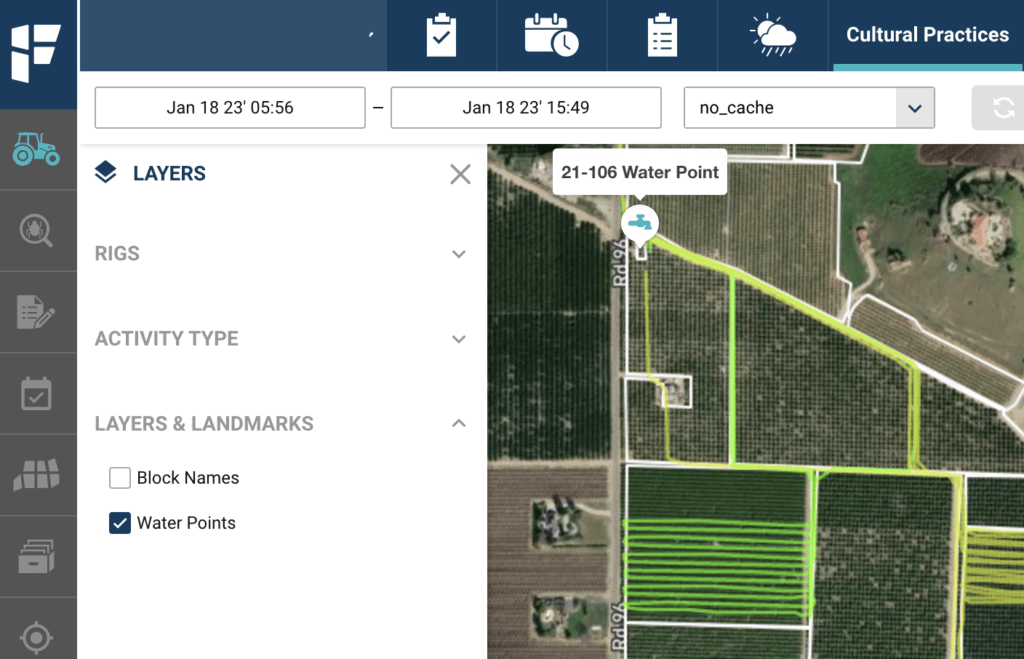

Take, for example, an orchard or vineyard with several fixed refill stations spaced around the blocks (see below image). All of the tractors have been driving to the Sherwood Water Point to refill their tanks. This water point has low pressure and it takes 12 minutes to refill a 600 gallon tank. However, there is an additional station in the northeast that appears to go unused, and this one is refilling a 600 gallon tank in 9 minutes. Re-routing tractors to the higher pressure refill station, which also happens to be closer in proximity for several of the tractors, could shave off significant time and mileage, while also reducing potential wait times at refill stations during shifts.

When you add all similar block inefficiencies over an entire season of 8-30 spray cycles, this time really adds up. In this example, apple growers with 25 spray cycles per acre per year and almonds growers with 8 spray cycles will pay an extra $30-$120/acre on this inefficiency alone, which can be optimized by changing behavior.

The graphic below illustrates how small improvements across refill and driving times can add up to significant bottom line savings for growers. In this specific example, shaving 3 minutes off of refill times and 3 minutes off of drive time to/from refills results in savings of $224,320 across the year ($150/acre).

Tracking refill activities to close gaps and get more strategic in field operations planning

Fieldin helps growers remove blind spots around refill activities so they can reduce unnecessary costs associated with inefficiencies. In the Fieldin app, users can see all of their refill stations as a separate layer in the map view (denoted by icon), enabling full visibility into refill activities within shifts.

With this data, supervisors and ranch managers can detect and measure potential inefficiencies related to:

- Average refill times at the operator level

- Acres per hour and shift efficiency, relative to refill times

- Distance to refill stations

- Average time spent at water points

Fieldin’s team of Grower Success Managers partner closely with customers to identify opportunities for improvement across their operations with regular reviews of key activities, including refills. By helping growers maximize their use of fill stations to improve efficiencies, they are able to lower their total cost per acre.

Once inefficiencies are identified, steps can be taken to make improvements that directly boost the bottom line. We’ve seen Fieldin customers drive efficiency improvements through activities such as staggering shift times to reduce wait time at refill stations, identifying and guiding operators to the closest refill station during shifts, and making strategic decisions around location of refill stations and whether to use fixed stations vs mobile nurse trucks.

There are obviously other factors to consider when it comes to placement and usage of refill stations, and with the added visibility that Fieldin provides into these operations, you can now make better-informed decisions based on data from the field.