Columbia Farm Services (CFS) is one of the largest and most comprehensive farm management companies in the Pacific Northwest, managing over 4,200 acres of tree fruit across owned and contracted properties. Their consulting and farm management services help growers modernize and optimize operations and management of their farms to maximize profitability and sustainability.

Columbia Farm Services Quincy orchard in late March

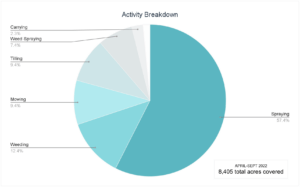

Last year, CFS deployed Fieldin on 300 acres of apple and cherry orchards in Quincy, Washington, and after a successful first year, they are expanding their total Fieldin deployment to 4,200 acres of apples and cherries. With the tools and insights that Fieldin is providing, they’ve gained greater visibility over their operations, allowing them to benchmark and improve operational efficiencies, introduce more sustainable practices, and use data to guide their planning and budgeting decisions.

“Fieldin is essential for daily planning of our operations. With the data provided, I know exactly how many people and machines to send into the orchard so we are maximizing our resources.”

Luis Diaz

Operations Manager, Columbia Farm Services

A bird’s eye view of orchard operations replaces time spent driving around

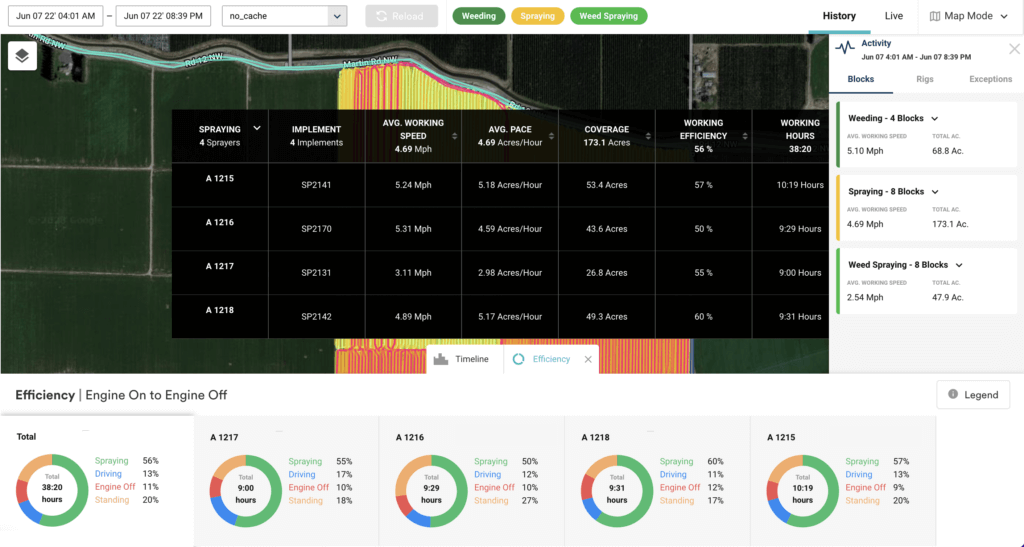

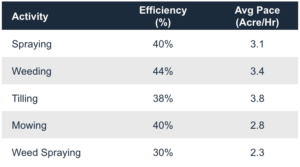

Luis Diaz is an Operations Manager at CFS’s Quincy ranch where he helps oversee planning and execution of mechanized activities in the orchards (e.g. mowing, spraying, weeding, weed spraying). In his role, Luis is often challenged with putting together logistical puzzles in order to keep up with the time-sensitive needs of the orchards. On a daily basis, he is tasked with ensuring that they have the right machines and people in the right place at the right time. Beyond just getting the jobs done, Luis is focused on maximizing the productivity and efficiency of their resources.

When Luis was introduced to Fieldin, he instantly saw the value that the smart farming operations solution could provide for their team. “Before Fieldin, I was constantly driving around the orchards to see where people were and what they were doing,” says Luis. “With Fieldin, I can see what everyone is doing right from my phone and know right away when something needs attention.”

Some of the specific real-time data points that Luis keeps tabs on are:

- Activity by block

- Speeds (especially in spraying where staying within recommended speeds is critical to the operation)

- Operator efficiency (uptime/downtime per operator using Fieldin’s driver keys)

- Time spent on a block

- Time spent refilling (read more in our previous article Refilling Sprayers – The unspoken inefficiencies in your operations)

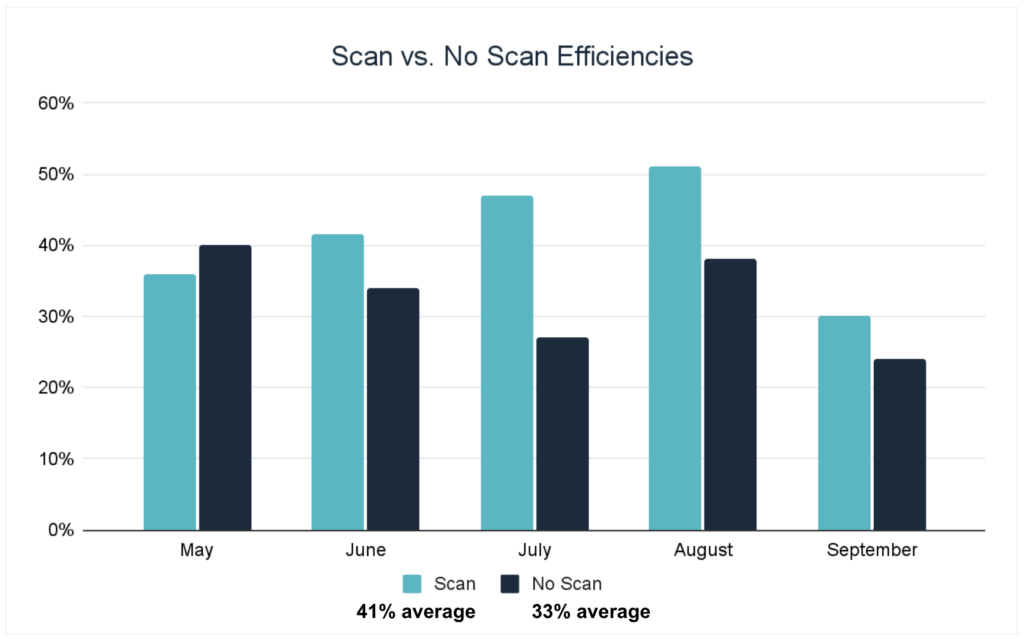

CFS uses Fieldin’s driver keys to connect operators with activities being performed. With increased accountability, they’ve been able to identify training opportunities to help increase efficiency across their entire crew. They’ve also been able to correlate an increase in efficiency when operators scan in with the driver keys. They saw an average work efficiency increase of 26% when operators scanned in versus when they did not.

An accompanying benefit of the solution that CFS has realized is the fuel savings and reduced engine hours on their trucks and ATVs as a result of not having to drive as much to oversee operations in the field.

CFS Quincy improves consistency, staying within 10% of target speeds, as a result of real-time monitoring

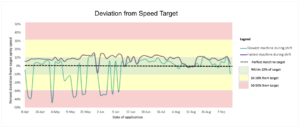

Once the CFS team gained visibility into machine speeds across their activities, they saw that there were significant deviations from the target speeds. In spraying, this is particularly problematic. In order for the spray to be effective, it requires adequate coverage of materials, and this directly depends on adhering to the speed defined in the spray recommendation. By spraying at too low of a speed, which was happening regularly (as shown in the graph below), they were applying too much chemical, resulting in material waste and potential damage to the crop.

After identifying the speed variance issues, they were able to implement improvements that have enabled them to remain within 10% of their speed targets.

Taking the guesswork out of operational planning

Today, Luis and his team rely on the data that Fieldin provides to organize their operational planning. Luis says that he used to lean on his intuition and experience to determine how many machines to send, but now with Fieldin, he can see exactly how many people and machines are needed to complete the job in the time frame allotted. “I used to say, ok, I need 3 sprayers. But the ranch needs to be sprayed in 8 hours, and I know it takes more than 8 hours with 3 sprayers. With Fieldin, I don’t have to guess anymore,” says Luis.

In addition to daily and weekly planning, the CFS team looks at summary reports to get a more holistic view of where their time is being spent, what they’re costs are, and where they have opportunities to improve. They also rely on this data to inform their budget planning for the coming season, guide rate schedules for their services, and evaluate taking on new contracts.

At a higher level, the CFS team is leveraging this data to inform their equipment investment decisions. In planning for the season, Luis’ manager will ask him, for example, if 5 sprayers are enough or if they need to invest in more. “I have all of the information I need to give him an accurate answer,” says Luis.

In our conversation with Luis, he was quick to point out the value that Fieldin’s Grower Success team has delivered alongside the technology, from support and training to strategic planning. “You guys have a great team. They go above and beyond to actively contribute to our success,” says Luis

Growing and innovating with Fieldin

As CFS expands deployment of Fieldin across more of their orchards in the Pacific Northwest this year, they will be looking to gain an even more holistic view of operations across their orchards. With cross-orchard data, they can now connect and compare operations to continuously improve efficiency, accuracy, and accountability across ranches.

The CFS team will also be rolling out Fieldin’s new Fleet Maintenance Module to help keep their equipment running at peak performance and to minimize machine downtime. They’re looking forward to transitioning from their pen-and-paper processes to a more streamlined system that eliminates gaps in their service scheduling and record-keeping.

“Some people are hesitant to adopt technology,” says Luis. “I believe in the power of technology to improve the way you do things.”