It’s 7:00 am on a warm spring morning in a pistachio orchard in California’s Central Valley. The spray crews are gearing up for a busy day and week ahead. This will be the first spray of the season for the fourth leaf pistachios. Last year, this application took a crew of five operators 360 hours as they hand-sprayed the young trees to avoid excess waste of materials. This year, they’re eager to try a new approach with Fieldin’s AutoSpray solution.

Since 2013, Fieldin has been paving the way for innovation in high-value crops. Following the acquisition of Midnight Robotics in 2021, we accelerated our push into the autonomous farming movement. At the beginning of 2023, Fieldin announced the largest deployment of retrofit autonomy kits for autonomous tractors to date with 100 retrofit kits made available to high-value crop growers. The retrofit kits are powered by lidar sensors that detect where the canopy starts and stops and turns spray nozzles on and off to only spray where needed.

With spraying operations being such a critical function for high value crop growers, we’ve been very intentional and targeted in the rollout of AutoSpray. As with any new technology, ensuring that the solution is doing its job requires close attention and collaboration with the teams in the field. Outside of the field operations, it’s important that we also ensure that we’re accurately capturing all of the data to understand the effectiveness of the AutoSpray programs.

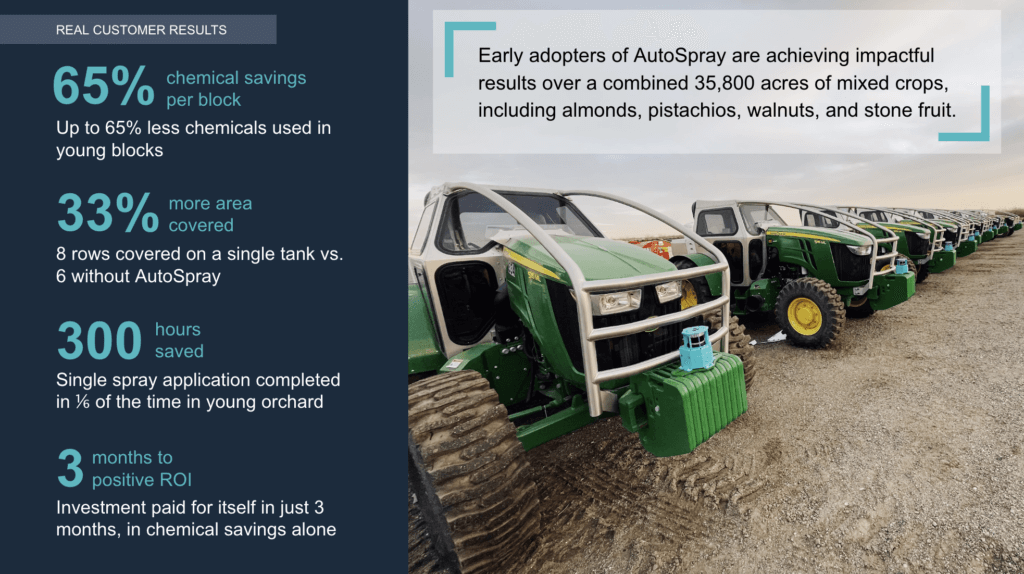

To date, the controlled rollout of AutoSpray solutions includes a combined 35,800 acres of mixed crops, including almonds, pistachios, walnuts, and stone fruit. As partners in the journey to autonomy, our team has been working closely with early adopters to ensure successful implementation and impact to growers’ bottom lines. The early results are impressive and show tremendous upside in being able to deliver on the promises that autonomous solutions, like AutoSpray, have been touting for high value crop growers.

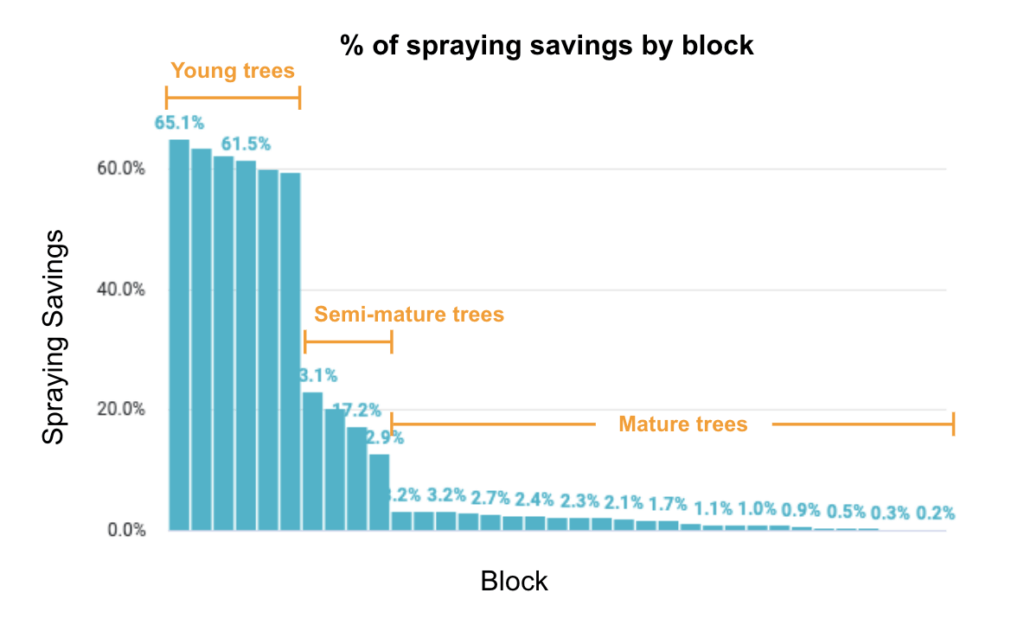

Savings abound across crop types and tree maturity profiles

Among the early adopters of AutoSpray, we’ve collected data across blocks of almonds, pistachios, walnuts, and stone fruit, each of which include a variety of young trees, semi-mature trees, and mature trees. As one might expect, the single most contributing factor determining the amount of chemical savings is the size of the trees. In younger blocks, there is a larger gap between trees which translates to more time with the nozzles off when AutoSpray mode is engaged and hence less material applied. In more mature blocks where the trees are larger, there is more active spraying occurring to cover the denser canopy. The graph below illustrates the distribution of AutoSpray chemical savings results across a pistachio orchard.

While the savings may be more substantial in young blocks, the savings we’ve seen in more mature blocks aren’t insignificant. For one grower, they were able to achieve 225 acres worth of material reduction in their large, mature blocks. Another grower saved an estimated $7,000 in chemical savings on a single application in 8-year old pistachios.

300 hours saved on a single spray application; 33% more area covered with a single tank

For the pistachio orchard that we referenced at the beginning of this article, the before and after of hand-spraying vs. AutoSpray has them only looking forward. The same spray that took their crew of five 360 hours to complete by hand last year took a crew of ONE only 24 hours to complete with AutoSpray, a savings over 300 of labor hours on a single application.

For another grower, they’re excited about the increased area that they’ve been able to cover on a single tank, which has reduced time and extra engine hours associated with excess refill activities. Without AutoSpray, they were covering 6 rows per tank; and now with AutoSpray, they’re able to cover 8 rows with the same size tank.

Both of these results demonstrate the value that AutoSpray can deliver beyond just material cost savings. Labor and machinery are other critical input cost reductions where AutoSpray is making an impact.

Early adopter achieves positive return on investment in just 3 months

With any investment, the key success criteria are the amount and timing of returns. Some of the factors playing into these are more easily measured than others. With AutoSpray, the material (i.e. chemical) cost savings are the most directly correlated and immediate returns that growers can expect to achieve. In fact, one of our early adopters realized a positive return on their investment–in chemical savings alone–in just three months, with still quite a bit more spraying operations remaining in the year. This investment return timeline doesn’t even factor in additional cost savings associated with labor and machinery.

Perhaps the greatest benefit of Fieldin’s AutoSpray solution is its approachability and affordability. Many of the other autonomous solutions on the market require large upfront investments in new machinery. With growers operating on increasingly slim margins, Fieldin has been committed to developing a solution that growers can take advantage of today by leveling up the equipment that they’ve already invested in.

AutoSpray offers a win-win for sustainability initiatives

With sustainability being a top priority for growers, the benefits that AutoSpray delivers are having an immediate and broad impact. By reducing the amount of chemicals used in their operations, growers are creating safer environments for employees and their farm ecosystems.

These benefits were highlighted in a feature published by Leading Harvest – In the Field with Triangle T Ranch. Among other Integrated Pest Management practices, Triangle T Ranch has implemented AutoSpray to improve precision and reduce overall chemical usage. After retrofitting their existing tractors with AutoSpray kits, they reduced chemicals in their spray applications by up to 24% per block in young orchards within the first two months.

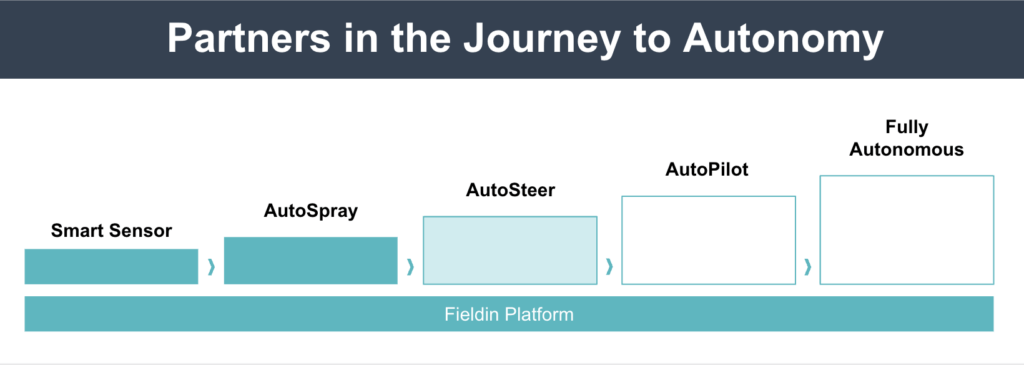

The journey to autonomy is just beginning

AutoSpray is just the beginning of the journey to autonomy, but marks an important milestone towards removing the dependency on an operator in the cab. For the early adopters, one of the biggest advantages that they’ve seen when embarking on this journey with Fieldin is the ability to get immediate value from the AutoSpray solution while also scaling towards increasingly automated processes.

“Much of the success with early adopters is that they’re bought into the long-term vision. There’s a strong sense of partnership built on mutual trust. We’re making sure the technology is sound and taking all of our proven results to the next step together.”

Nick Rocca

Head of US Autonomy, Fieldin

Next steps for these growers is AutoSteer, which we’ll start rolling out with existing AutoSpray customers at the end of 2023. As the name suggests, AutoSteer builds on AutoSpray by controlling the steering function of tractors through blocks, enabling steady steering up and down rows and precision turns between rows. Once the AutoSteer function is dialed in, we’ll look to engage full AutoPilot mode with an operator overseeing functions in the cab, and then onto Fully Autonomous mode where we remove the operator from the cab entirely. This journey doesn’t happen overnight, and there are many considerations at each step.

While our early adopters will continue to advance on their autonomy journeys, we will also be expanding the rollout of AutoSpray to qualified partners. If you are a grower who is interested in starting your autonomy journey, please reach out.