Spraying operations in orchards and vineyards involve a complex mix of logistical planning, chemistry, equipment calibration, operator precision, real-time tracking, and verification processes. One small mistake or oversight can translate to extreme consequences for crop health and revenue. With so many factors to consider, a diverse set of spraying automation solutions are helping growers improve accuracy and efficiency in their operations. One such area is in automatic rate control.

Without automatic rate control, many ranch managers and spray supervisors rely on tedious guess-and-check calibration processes to dial in the exact pressure and flow settings to achieve the intended output for a given spray application. Multiply this process across every machine and spray in a given season, and it adds up to significant time spent, not to mention the inherent inaccuracies that come with this on-the-fly approach.

Speaking of inaccuracies, we spoke with a large nut grower in California who conducted an ROI analysis upon first adopting automatic rate control technology. They looked at variability between use reports (pen & paper accounts of how much material they mixed each night) versus the spray recommendations and said they were commonly coming in +/- 25%. They knew this variability was costing them either in wasted chemical or in too little chemical applied which impacted crop quality and yield. Prior to implementing automatic rate control, they had tried to confirm speeds based on their internal calibration methods, but it was too difficult and didn’t provide them with the real-time insights that they needed to correct issues as they happened.

With precision as the make-or-break for successful spray applications, automatic rate control technologies help remove some of the guesswork, management, and human error that plague many growers today.

Automatic rate control technologies help improve consistency across machines, operators, and diverse terrain

With so many factors outside of their control–inflation, water scarcity, weather events, labor availability, market conditions–growers must constantly battle for stability and consistency in their operations. Automatic rate control technologies are one small way for growers to achieve better consistency in their spraying operations, which can have a big impact on overall crop health.

Overcoming labor skills gaps

Operating tractors and spraying equipment requires a unique set of skills and training, and comes with a lot of responsibility and accountability. Ranch managers and spray supervisors are constantly working to hire and upskill employees to fit these roles, which means there are often big disparities in experience levels among operators.

One of the most important factors in spray applications is adhering to the prescribed speed on a given spray recommendation. Even small fluctuations in operators’ speeds can translate to big impacts on chemical costs and crop health. Driving too fast leads to under-application, and too slow deposits too much material on the crop. Automated rate control technologies compensate for speed inconsistencies by adjusting the flow accordingly.

Compensating for variability in diverse terrain

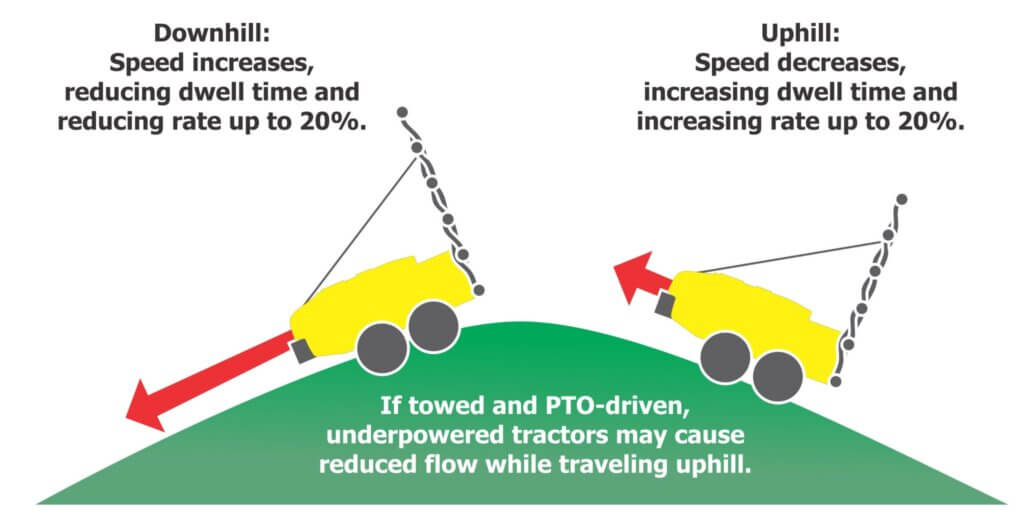

Automated rate control technologies have added benefits in orchards and vineyards with variable terrain. “Hilly operations create highly variable application rates. Changes in travel speed can translate to 40% variability in rate applied. Rate controllers adjust flow to compensate,” states Mark Ledebuhr, spray technology expert and co-author of Airblast 101: Guide to Effective and Efficient Spraying.

Image Source: https://sprayers101.com/controller-air-assist/

Mark goes on to say, “Even a modest improvement represents a quick return on investment. Equally important, a more consistent application reduces the risk of higher residue levels on the uphill and improves crop protection on the downhill.”

Right-sizing chemical usage

With chemical costs skyrocketing in recent years, growers can’t afford any waste when it comes to spray applications. At the same time, they don’t want to be left with a surplus of materials that would indicate under-application. Automated rate control technologies are an excellent way to ensure the right amount of materials are being applied across all spray campaigns. This plays a critical role in regulatory reporting, budgeting, planning, and sustainability initiatives.

Are U.S. growers playing catch-up with global peers?

Rate control technologies are not new, but their adoption varies dramatically across the globe. For example, in Australia, where there is high turnover in labor from year-to-year, rate controllers have become somewhat standard among orchard and vineyard operations. However, in the Western U.S., adoption has lagged substantially in comparison. In fact, in the previously referenced article, Mark Ledebuhr says, “less than 10% of air-assist sprayers have rate controllers.”

Some of the reasons cited for the lag in adoption include:

- Poor experience in the past: Many growers have tried rate controllers on air-blast sprayers at some point in their career, and some will say that they didn’t see the expected value. Whatever the reason for the poor experience (e.g. using mismatched components, receiving poor guidance on effective use, mistrust in data, poor visibility into what the rate controllers were actually doing), rate control technologies on air-blast sprayers have come a long way. Installations are easier, maintenance is minimal, and intuitive interfaces streamline the operational components.

- Investment cost: With tight margins crippling many growers, investment decisions center around necessity and ROI. Some view rate controllers as a nice-to-have, claiming that they can do a nearly equivalent job by adhering to strict processes and protocols. While some teams may be able to get close, it’s always advised to conduct a proper analysis with real data to expose potential opportunities for improvement. Rate controller advocates claim that the ROI is clear and quick.

- Perceived maintenance and calibration requirements: One of the common objections to rate controllers is the perception that they require burdensome schedules of maintenance and complex calibration processes. Based on some of our recent conversations with growers on both sides of the rate controller adoption line, there doesn’t seem to be a clear delineation as to one being more or less complex than the other. All spray equipment requires regular cleaning, maintenance, and calibration, regardless of whether rate controllers are in use or not.

- Speed, pressure, and nozzle performance: While rate controllers are good at making minor, on-the-fly adjustments to pressure to maintain consistent application volumes, pressure should not be used to make significant changes to flow rate. It’s important that operators understand the relationship between changes in pressure and nozzle performance and their effects on spray coverage. Additionally, real-time speed alerts can help keep operators within the rate controller’s threshold of pressure adjustments. (For a more in-depth read on this topic, check out this article.)

- Adapting instructions to block profiles: Rate controllers require operator inputs in order to adapt the specs of a given spray recommendation to individual block characteristics (e.g. row width). For many growers who struggle to retain consistent, skilled labor, relying on operators to input the correct settings and ensure that the rate controllers are doing their jobs introduces too much risk into the operation. Emerging technologies that automatically deploy instructions to equipment are helping remove the risk of human error while also streamlining the flow from spray rec to task execution.

Why now is the right time to invest in Auto-Rate technologies

Times are tough for many high value crop growers, and tough times call for innovative measures. Due to the critical role that it plays in farming operations, spraying is not an area where growers can cut back on spending. In fact, as one of the most important and expensive operations on the farm, it’s the precise area where growers should be focusing their investments on optimization.

To identify opportunities for optimization, growers must first understand their current situation. Here are some starting questions to help assess whether Auto-Rate technologies might present opportunities for improvement:

- How do you measure actual applied rates today? How confident are you in the accuracy of this data?

- How do you ensure operators are driving the instructed speeds during spraying operations? If they’re off, how do you assess the impact to costs and crop health?

- How are you calibrating your spraying equipment today to ensure proper application rates? How much time does this take you throughout the season?

- How variable is the terrain in your orchard or vineyard? If hilly, how are your operators adjusting for uphill/downhill speeds to keep application rates consistent?

Extending the benefits of Auto-Rate solutions

Rate control technologies on their own offer many advantages for growers. However, they are most effective when integrated within a comprehensive, highly automated, end-to-end spraying program. From scouting and spray recommendations to resource planning, precision execution, and robust insights, automation that is powered by robust ground-truth data helps growers streamline and verify the full cycle of their spraying operations, giving them peace of mind that every spray is done right.